Maintenance management is evolving rapidly, and businesses can no longer rely on manual processes or outdated systems. CMMS software has become an essential tool for organizations aiming to improve asset performance, reduce downtime, and streamline maintenance operations. From small facilities to large enterprises, CMMS solutions help teams manage work orders, track assets, and schedule preventive maintenance more efficiently.

With the rise of AI, automation, and cloud-based platforms, modern CMMS software now delivers far more than basic maintenance tracking. It provides real-time insights, predictive capabilities, and mobile access that enable maintenance teams to make smarter, data-driven decisions. This guide covers everything you need to know about CMMS software in 2026, including key benefits, emerging trends, and how to select the right solution for your business.

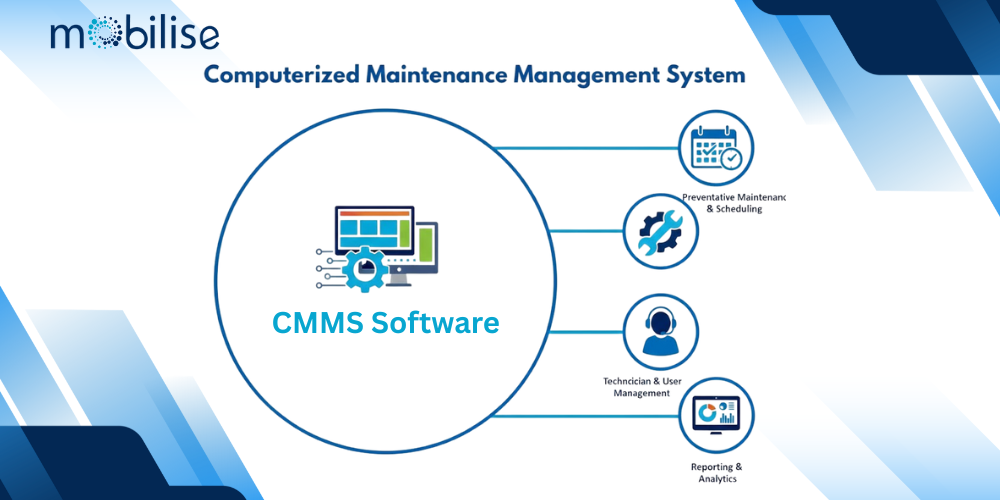

What Is CMMS Software?

A Computerized Maintenance Management System (CMMS) is a software-based solution that helps organizations efficiently manage, monitor, and maintain their equipment, assets, and facilities. It enables maintenance teams to plan, track, and execute maintenance activities through a centralized digital platform.

This system organizes maintenance operations, streamlines workflows, reduces paperwork, and improves communication across teams. By providing accurate data and actionable insights, it supports cost-effective decision-making while helping businesses maintain asset reliability and operational efficiency.

Enterprise Benefits of CMMS Software

CMMS software helps enterprises streamline maintenance operations, reduce operational risks, and improve asset performance through structured and data-driven processes.

- Reduces unplanned equipment downtime by enabling preventive and scheduled maintenance.

- Centralizes maintenance data, making asset information easily accessible across teams.

- Improves maintenance team productivity through organized work orders and clear task priorities.

- Enhances communication between technicians, supervisors, and management.

- Supports cost control by tracking maintenance expenses and spare parts usage.

- Extends asset lifespan through timely inspections and condition-based maintenance.

- Provides detailed reports and insights to support compliance and strategic decision-making.

Latest CMMS Software Trends in 2026

Maintenance management continues to evolve as organizations adopt smarter, more connected, and data-driven technologies to improve reliability and efficiency.

AI-Driven Maintenance Intelligence

Artificial intelligence is being used to analyze maintenance data, predict failures, and recommend actions that reduce downtime and maintenance costs.

Cloud-Based Maintenance Platforms

Cloud technology enables real-time access to maintenance data, improves collaboration, and supports scalability without heavy infrastructure investment.

Mobile-First Maintenance Management

Mobile applications allow technicians to manage work orders, update tasks, and access asset data directly from the field.

Predictive and Condition-Based Maintenance

Advanced analytics help organizations move beyond preventive schedules by maintaining assets based on real-time condition data.

IoT Integration for Real-Time Monitoring

Connected sensors provide continuous equipment data, enabling faster responses and improved asset performance.

Data-Driven Reporting and Dashboards

Custom dashboards and automated reports help maintenance teams track KPIs and make informed decisions.

AI-Powered CMMS Solutions

AI-powered CMMS solutions are transforming maintenance management by providing predictive insights, automating tasks, and optimizing resource allocation. These systems help organizations move from reactive maintenance to a proactive, data-driven approach.

- AI analyzes historical maintenance data to predict potential equipment failures.

- It automatically prioritizes work orders based on urgency and impact.

- Machine learning identifies patterns that help optimize maintenance schedules.

- AI assists in inventory management by predicting parts usage and replenishment needs.

- Predictive insights reduce unplanned downtime and extend asset life.

- Intelligent notifications guide technicians to take timely, precise actions.

- Data-driven recommendations improve decision-making for managers and executives.

The Role of AI and Automation in CMMS Software

AI and automation are revolutionizing maintenance management by reducing manual tasks, increasing accuracy, and helping teams make proactive decisions. Modern CMMS platforms use AI to predict failures, optimize schedules, and provide actionable insights, while automation ensures maintenance processes run smoothly and efficiently.

| Feature | Description | Benefit |

|---|---|---|

| Predictive Maintenance | Uses AI to forecast equipment failures before they happen | Reduces unplanned downtime |

| Automated Work Orders | Automatically generates and assigns tasks | Saves time and improves task tracking |

| Intelligent Scheduling | Prioritizes maintenance tasks based on asset criticality | Optimizes team productivity |

| Inventory Management | Predicts parts usage and triggers reorder | Prevents stockouts and delays |

| Data-Driven Insights | Analyzes maintenance trends and KPIs | Supports better managerial decisions |

| Remote Monitoring | IoT sensors provide real-time asset data | Enables faster response to issues |

| Continuous Optimization | AI learns from past data to improve maintenance plans | Increases asset lifespan and efficiency |

Five Industry Use Cases for CMMS

CMMS software is versatile and can be applied across a wide range of industries to streamline maintenance, reduce downtime, and optimize asset performance. Different sectors leverage CMMS features to meet their unique operational challenges and regulatory requirements.

Manufacturing

In manufacturing, CMMS helps schedule preventive maintenance, track machine performance, and minimize production downtime.

Facilities Management

Facilities teams use CMMS to manage building systems, plan maintenance tasks, and ensure regulatory compliance.

Healthcare

Hospitals and clinics rely on CMMS to maintain medical equipment, track inspections, and ensure patient safety.

Energy & Utilities

Energy companies use CMMS to monitor critical infrastructure, schedule preventive maintenance, and reduce outages.

Transportation & Logistics

Transport and logistics firms apply CMMS to maintain vehicles, track service history, and ensure fleet reliability.

Why OpsSuite Is the Best CMMS Software in 2026

OpsSuite stands out as a leading CMMS solution because it combines powerful features, ease of use, and modern technology to meet the needs of maintenance teams across industries. Its intuitive interface allows technicians, managers, and executives to access real-time data, track work orders, and manage assets efficiently, all from a single platform.

In addition, OpsSuite leverages AI and automation to optimize maintenance schedules, predict equipment failures, and reduce downtime. With mobile access, cloud-based deployment, and comprehensive reporting tools, OpsSuite helps organizations save costs, improve productivity, and make data-driven decisions, making it the top choice for businesses in 2026.

CMMS vs. EAM

Maintenance management software comes in different types, with CMMS (Computerized Maintenance Management System) and EAM (Enterprise Asset Management) being the most common. While both help organizations manage assets and maintenance, they serve different purposes and offer unique features. Understanding the differences can help businesses choose the right solution based on their operational needs.

| Feature | CMMS (Computerized Maintenance Management System) | EAM (Enterprise Asset Management) |

|---|---|---|

| Primary Focus | Maintenance operations and work orders | Full lifecycle asset management |

| Asset Scope | Limited to critical equipment | Covers all physical assets, including facilities |

| Reporting & Analytics | Basic maintenance reports | Advanced analytics, asset performance, and ROI tracking |

| Cost | Generally more affordable | Typically higher cost due to broader features |

| Implementation | Quick and simple | Longer, more complex deployment |

| Users | Maintenance teams and supervisors | Maintenance, operations, finance, and management |

| Use Case | Daily maintenance, preventive schedules, and asset tracking | Strategic planning, capital projects, and enterprise-wide asset optimization |

Conclusion

A modern maintenance strategy needs more than spreadsheets — it requires a system that improves efficiency, reduces downtime, and provides data-driven insights. Try a demo of OpsSuite by Mobilise at https://mobilise.co.in/ to experience preventive planning, real-time tracking, and AI-powered maintenance tools that help your team work smarter and stay ahead.

As someone who works in facilities management, I’ve seen firsthand how essential a CMMS can be. But what really excites me about the newer systems is their ability to predict potential issues before they happen. I’m curious how much these predictive features are being used across industries.

Loved this guide—super relevant and spot on for where CMMS is headed in 2026! 🚀 The focus on AI, mobility, and data-driven maintenance really stands out and adds great practical value. This is a must-read for teams looking to modernise operations and drive real efficiency. Fantastic work! 👏💡